Choosing the right panel material makes a big difference in durability, finish and long-term cost for kitchens, wardrobes and furniture. Two popular choices in India right now are Action TESA HDHMR (high-density, high-moisture-resistant engineered board) and Century Sainik 710 plywood (a widely used BWP plywood from CenturyPly). Both have strengths — the trick is matching the material to the job.

This article compares them across composition, performance, applications, cost, installation considerations and gives clear recommendations so you can pick the right product for each project.

Quick snapshot — when to use each

- Action TESA HDHMR — best for kitchen carcasses, bathroom cabinets, laminate/CNC friendly surfaces and anywhere you need superior moisture resistance and smooth finish.

- Century Sainik 710 plywood — best for carcasess, shutters, door cores, shelving and structural parts where traditional plywood strength, termite protection, veneer finish or cost matters.

Table of Contents

Action TESA HDHMR vs Century Sainik 710 Plywood

1. What are these products?

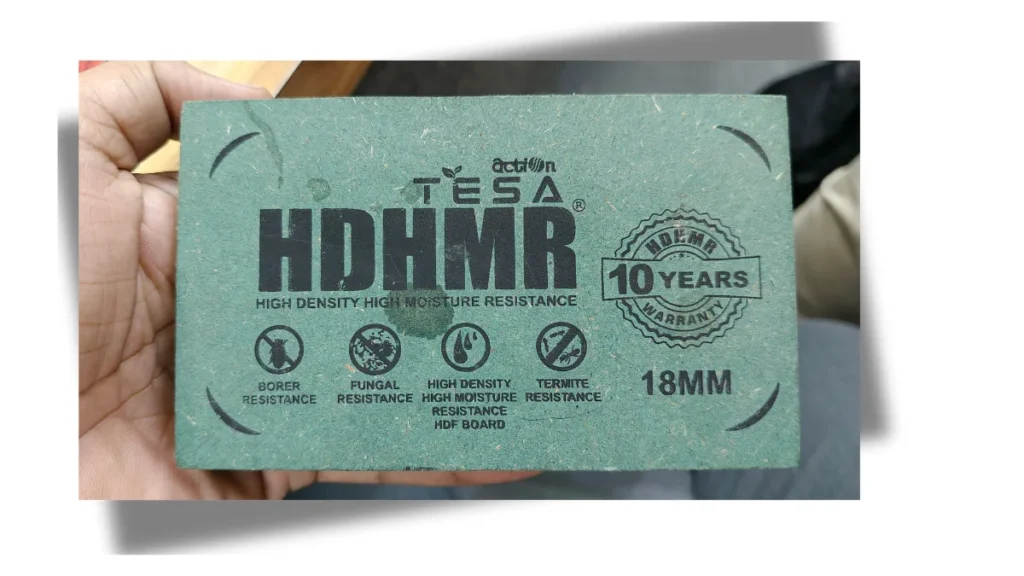

Action TESA HDHMR

- HDHMR stands for High-Density High-Moisture Resistant board. It’s an engineered panel (HDF/HMR style) manufactured under pressure with special resins to give higher density, uniform core and enhanced moisture resistance compared to standard particle board or MDF.

- Designed for heavy-duty interior use — especially carcasses, panels and places needing excellent screw holding and smooth finish.

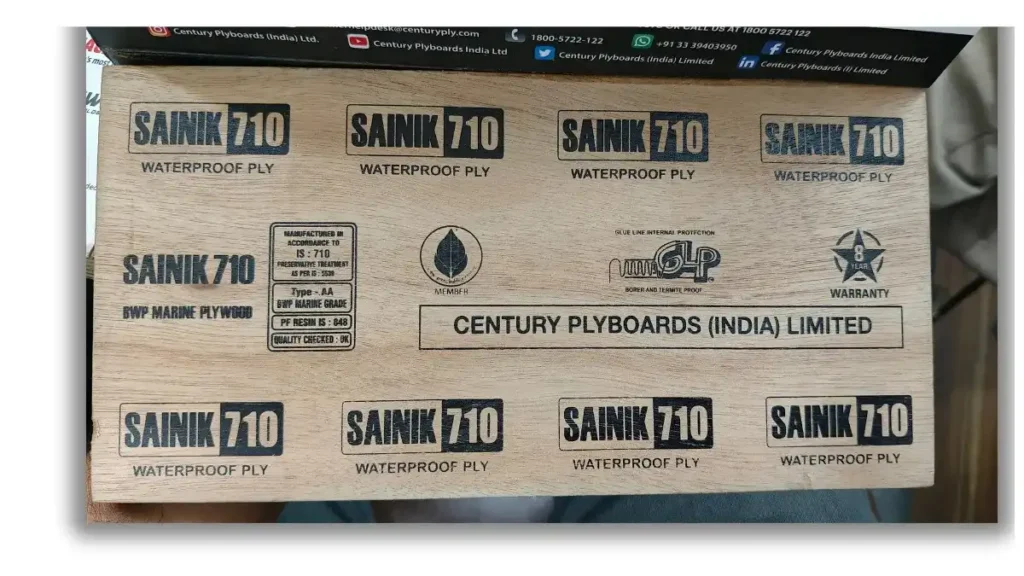

Century Sainik 710 Plywood

- Sainik 710 is CenturyPly’s popular BWP plywood range (IS:710 grade), positioned as a value, reliable plywood for many interior uses. It’s made of cross-laminated veneers bonded with waterproof adhesive to meet BWP requirements.

- Widely available, economical and familiar to carpenters across India.

2. Material & manufacturing differences

| Aspect | Action TESA HDHMR | Century Sainik 710 Plywood |

| Core type | Engineered HDF/HDHMR core (uniform) | Cross-laminated wood veneers |

| Density | High — denser and heavier than standard Plywood | Moderate — depends on veneer & glue, lighter than similar-density HDHMR |

| Surface | Ultra smooth, laminate/CNC friendly | Veneer surface (can be laminated/veneered) |

| Water Proof | No, only resistant to water | BWP grade — water and termite-proof plywood |

| Dimensional uniformity | Very consistent (factory-made) | Some natural variation due to veneers |

| Screw holding | Excellent | Good (but slightly less than HDHMR of comparable density) |

| Borer and Termite Proof | No, only resistant | Yes, borer and termite protection |

| Warranty | 10 Years | 8 Years |

Note: exact density and technical specs vary by product variant and batch — always check manufacturer technical data sheets for the precise numbers you need.

3. Performance: water, strength, finish, screw holding

- Moisture resistance: Action TESA HDHMR is engineered specifically for moisture resilience and edge stability; it typically handles humid conditions better than standard MR plywood. Sainik 710 is a BWP (Boiling Water-Proof) plywood for interior use. Sainik 710 also has termite-proof properties.

- Strength & load bearing: Plywood’s cross-laminated structure gives it very good bending strength and resistance to splitting in load-bearing applications (shelves, carcasses). HDHMR is stiffer and denser—great for shutters and panels, but heavier for large structural spans.

- Screw holding & fittings: HDHMR usually has superior screw retention due to uniform high density. Plywood still performs well but can loosen over many cycles if of lower density or poor quality.

- Finish & machining: HDHMR offers a smoother, more predictable surface for laminates, paints and CNC routing. Plywood gives a natural veneer look — preferred where wood aesthetics are required.

4. Typical applications & project recommendations

Use Action TESA HDHMR for:

- Kitchen carcasess, small size shutters and cabinet doors

- Bathroom vanities and wet-zone shutters (with good edge sealing)

- CNC-cut decorative panels and TV units

- Any surface requiring perfect laminate adhesion or paint finish

Use Century Sainik 710 plywood for:

- Internal carcasses, shutters, shelving, and structural frames

- Door cores, solid laminated surfaces where veneer look is wanted

- Cost-sensitive projects where plywood’s traditional strength is valuable

Hybrid approach (recommended):

- Carcass: Action TESA HDHMR (cost-effective, strong)

- Shutters/doors: Century Sainik 710 plywood (smooth, waterproof)

This mix gives a balance of cost, finish and longevity.

5. Price & availability

- Price: In many markets, HDHMR boards are slightly lower per sq ft than mass-market Sainik 710 plywood, but not always — local dealer pricing, freight and thickness influence final cost.

- Availability: Century Sainik plywood is widely available through plywood shops and distributors. Action TESA HDHMR availability depends on dealer network but has grown steadily — confirm stock before quoting

6. Installation & handling tips

- Edge sealing: Seal all exposed edges (both materials) with PU edge sealer or edge banding to prevent moisture ingress — this is especially critical for long life.

- Fasteners: Use recommended screws for HDHMR (confirm pilot holes where needed) and use glue grades recommended for plywood carcasses.

- Storage: Store panels flat, off the ground and covered — even moisture-resistant panels should not be left in standing water.

- Cutting & CNC: Use sharp carbide cutters; HDHMR gives very clean cuts but can blunt tools faster because of density.

7. Pros & cons summary

Action TESA HDHMR

- Excellent moisture resistance and screw holding

- Ultra smooth surface — best for laminates & CNC

- Consistent, engineered quality

– Heavier to handle; price may be higher than budget plywood

Century Sainik 710 Plywood

- Traditional strength for load-bearing parts

- Veneer finish options; widely available and economical

- Familiar to carpenters and clients

– MR grade is not fully waterproof; surface uniformity varies with veneer

Find out which is better in Action TESA HDHMR vs Sainik MR.

8. Final recommendation

In Action TESA HDHMR vs Century Sainik 710 plywood comparison, most modern interiors, the best practice is a hybrid: use Action TESA HDHMR for carcasses and structural elements, and Century Sainik 710 for shutters, doors and panels that need a premium finish and moisture resilience. If the job is fully wet/exposed (continuous water contact), consider WPC or marine-grade products instead

FAQ

Can HDHMR replace plywood everywhere?

Technically possible for many surfaces, but plywood still excels in some structural or veneered aesthetic uses. Use the right board for the right function.

Which is lighter?

Sainik plywood is generally lighter than a high-density HDHMR panel of the same thickness.

Do these products need special adhesives?

Use adhesives and laminating glues recommended by manufacturers — HDHMR often requires PVA/PU adhesives compatible with its surface; check technical sheets.

Which is better value long term?

If moisture and finish are key, HDHMR gives better long-term value despite higher upfront cost. For general furniture and non-wet areas, Sainik 710 plywood is cost-efficient.

In 2025, Stake Casino has become a go-to platform for Indian players. To enter the official website, simply open the official entry point here — How Indian players win big at Stake Casino – 2025 strategies

. It’s the easiest way to begin. With thousands of exciting games, a hassle-free layout, and local transaction options, the casino stands out in the digital casino industry. “Spin classic titles and hit jackpots now!”

In addition, Stake consistently updates features to enhance gameplay for Indian users, offering smoother navigation and better accessibility across devices.

Stake Sign-Up for Indian users | Simple Setup

Creating an account at Stake is straightforward, allowing new users to place your first bets within minutes. Just follow the access point through the trusted entry mentioned earlier, then tap Register, fill in your details, verify your account, and finally add funds to unlock the platform.

“Create your account fast and claim your welcome offer!”

If you prefer mobile use, Stake’s registration also works smoothly on smartphones, so you can complete the process anytime.

Stake Bonuses for India | Unlock Lucrative Promotions

The welcome bonus is among the key benefits new users choose Stake. Indian players can instantly get extra funds with offers tailored for the local audience.

• Welcome Bonus Package — Receive a deposit bonus up to the maximum bonus limit.

• Free Spins Offers — Receive complimentary spins on selected games.

• VIP & Loyalty Program — Earn points for each bet, then redeem bonuses.

“Grab a 100% bonus to explore the casino!”

Stake also provides seasonal and festival promotions specifically for Indian users, giving extra chances to earn rewards.

In 2025, Stake Casino has become a go-to platform for Indian players. To securely access the platform, simply open the official entry point here — Stake Casino’s 2025 edge: fair games, fast support, and Indian player focus

. It’s the quickest path to begin. With a massive game library, a hassle-free layout, and local transaction options, the casino stands out in the online gaming space. “Spin popular slots and win big instantly!”

In addition, Stake consistently updates features to enhance gameplay for Indian users, offering smoother navigation and better accessibility across devices.

Stake Sign-Up for Indian users | Simple Setup

Registering at Stake is lightning-fast, allowing Indian players to begin your gaming journey within minutes. Just visit the platform through the verified gateway at the top, then tap Register, enter your basic info, confirm your email, and finally make your first deposit to start playing instantly.

“Create your account fast and claim your welcome offer!”

If you prefer mobile use, Stake’s registration also works smoothly on smartphones, so you can complete the process anytime.

Stake IN Promotions | Unlock Rewarding Benefits

The welcome bonus is among the biggest advantages new users choose Stake. Players from India can instantly get extra funds with offers tailored for the local audience.

• Welcome Bonus Package — Get a 100% match up to ?10,000.

• Free Spins Offers — Play with extra rounds on featured titles.

• VIP & Loyalty Program — Earn points for each bet, then unlock exclusive perks.

“Grab a 100% bonus to explore the casino!”

Stake also provides seasonal and festival promotions specifically for Indian users, giving extra chances to earn rewards.

Mail – mahavirsharma7227@gmail.com

Today, Stake Casino has become a favoured site for gamblers in India. To securely access the platform, simply use the trusted access page here — [url=https://stakejackpotclub.org/in/]Play the newest Stake Casino games in India 2025 with instant withdrawals[/url]

. It’s the quickest path to begin. With a massive game library, a smooth interface, and support for Indian methods, the casino remains a leader in the online gaming space. “Enjoy live dealer tables and earn instant rewards today!”

In addition, Stake consistently updates features to enhance gameplay for Indian users, offering smoother navigation and better accessibility across devices.

Stake Registration for Indian users | Simple Start

Registering at Stake is straightforward, allowing new users to start playing within minutes. Just follow the access point through the trusted entry mentioned earlier, then tap Register, fill in your details, confirm your email, and finally top up your balance to grab your welcome bonus.

“Sign up in a minute and get your free spins!”

If you prefer mobile use, Stake’s registration also works smoothly on smartphones, so you can complete the process anytime.

Stake Bonuses for India | Unlock Rewarding Deals

The sign-up reward is among the key benefits new users choose Stake. Indian players can instantly get extra funds with offers tailored for the local audience.

• Welcome Bonus Package — Get a 100% match up to 10,000 INR.

• Free Spins Offers — Enjoy additional spins on featured titles.

• VIP & Loyalty Program — Collect rewards for consistent play, then redeem bonuses.

“Double your first deposit to extend your gameplay!”

Stake also provides seasonal and festival promotions specifically for Indian users, giving extra chances to earn rewards.

In 2025, Stake Casino has become a popular choice for gamblers in India. To start playing safely, simply open the official entry point here — [url=https://stakebettingaustralia.com/in/]Claim your Stake Casino India 2025 welcome package immediately[/url]

. It’s the safest method to begin. With thousands of exciting games, a smooth interface, and local transaction options, the casino remains a leader in the competitive iGaming market. “Spin popular slots and earn instant rewards instantly!”

In addition, Stake consistently updates features to enhance gameplay for Indian users, offering smoother navigation and better accessibility across devices.

Stake Sign-Up for Indian users | Quick & Easy Start

Signing up at Stake is lightning-fast, allowing you to begin your gaming journey within minutes. Just follow the access point through the verified gateway at the top, then tap Register, enter your basic info, activate your profile, and finally make your first deposit to unlock the platform.

“Sign up in a minute and get your free spins!”

If you prefer mobile use, Stake’s registration also works smoothly on smartphones, so you can complete the process anytime.

Stake Bonuses for India | Unlock Attractive Benefits

The initial promotion is among the biggest advantages new users choose Stake. Indian players can instantly increase their balance with offers tailored for the local audience.

• Welcome Bonus Package — Receive a deposit bonus up to 10,000 INR.

• Free Spins Offers — Receive complimentary spins on selected games.

• VIP & Loyalty Program — Collect rewards for consistent play, then unlock exclusive perks.

“Double your first deposit to play more games!”

Stake also provides seasonal and festival promotions specifically for Indian users, giving extra chances to earn rewards.

Very well-explained comparison! This blog clearly highlights where Action TESA HDHMR performs better and where Century Sainik 710 plywood is the smarter choice. The practical recommendations and hybrid approach make it easy for homeowners and contractors to pick the right material for each part of a project.