When you’re building kitchens, wardrobes, cabinets or commercial interiors, choosing the right core material matters more than price alone. Two popular options in India are Sainik MR plywood (moisture-resistant plywood) and Action TESA HDHMR (High-Density, High-Moisture-Resistant engineered board). Both advertise moisture protection and durability – but they’re different materials with different strengths, weaknesses and ideal use cases.

This article gives a straightforward comparison (features, performance, cost considerations, and recommended applications) so you can pick the right material for your project.

Action TESA HDHMR vs Sainik MR Plywood – Quick Summary

- Sainik MR plywood – best if you want a traditional plywood construction (veneered/laminated), good screw holding, and broadly available in local markets. Better for structural use and where edge finishing/veneering matters.

- Action TESA HDHMR – engineered high-density board with superior moisture resistance (HMR/HDR), excellent for modular kitchens, cabinet shutters, and CNC routed decorative work where smoothness and dimensional stability matter.

Core differences (material & manufacturing)

Sainik MR plywood

- Composition: Multiple layers (veneers) of wood glued together using resin adhesives; top layers are chosen for veneer finish.

- MR grade: Glue & manufacturing tuned for moderate moisture resistance (suitable for interior use and occasional dampness). Not fully waterproof.

- Typical density: Lower than HDHMR boards; strength comes from cross-laminated veneer structure.

- Finish: Veneer surface can be polished, laminated or veneered.

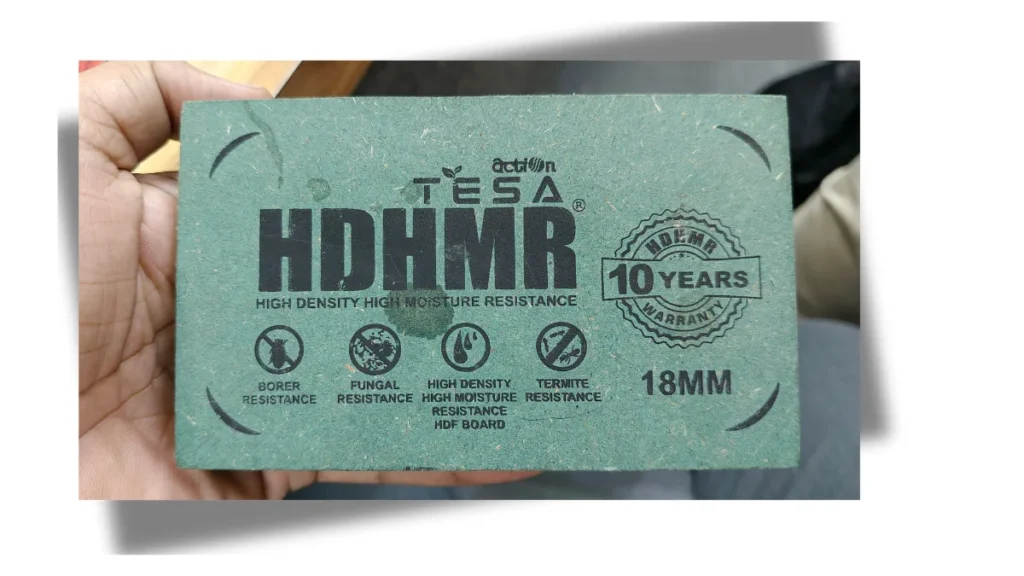

Action TESA HDHMR (HDHMR board)

- Composition: Engineered high-density fiber/particle core specially formulated for moisture resistance; manufactured using higher pressure and specialized resins.

- HDHMR: Designed specifically for high moisture resistance, with density and formulation optimized for screw holding, no chipping and dimensional stability.

- Typical density: Higher than standard MDF/particle board and many plywoods—gives better screw retention and rigidity.

- Finish: Ultra smooth — ideal for laminates, paints, veneers and CNC routing.

Performance comparison (table)

| Feature | Sainik MR Plywood | Action TESA HDHMR |

| Material Type | Cross-ply veneers (plywood) | Engineered high-density board (HDHMR) |

| Moisture Resistance | Moderate (MR grade) | High (HDHMR grade) |

| Density & Rigidity | Good (ply structure) | Higher density – very rigid |

| Screw holding | Good | Excellent (better) |

| Edge finish | Needs edge banding; veneered looks good | Smooth, clean edges; easy for edge binding |

| CNC routing | No | Excellent – clean routing |

| Termite/Borer resistance | Yes | Typically treated – good resistance |

| Weight | Lighter than equal-density HDHMR | Heavier (denser) |

| Price (general) | Mid – widely available | Often comparable or slightly higher |

| Best for | Structural frames, door cores, where veneer look required | Modular kitchen cabinets, CNC panels |

| Availability | Very high (local dealers) | Very Good (authorised dealers) |

Find the best in Action Tesa HDHMR vs Sainik 710

Practical pros & cons

Sainik MR plywood – Pros

- Traditional, trusted option for decades.

- Strong in tension and flexure (good for frames and load-bearing parts).

- Veneer finish looks premium; easy to match to solid wood aesthetics.

- Easier to source from local plywood shops.

Sainik MR plywood – Cons

- MR is not fully waterproof – prolonged exposure to moisture can cause delamination.

- More variability between batches/brands.

- Slightly lower screw retention than high-density engineered boards.

Action TESA HDHMR – Pros

- High density and engineered uniformity – excellent screw holding and no chipping.

- Specifically formulated for moisture resistance – better for wet kitchens, utility areas.

- Smooth surface ideal for laminates and CNC work; fewer finishing surprises.

- Typically low formaldehyde emissions (check certifications).

Action TESA HDHMR – Cons

- HDHMR are relatively new in the market.

- Edge finishing for visible edges requires edge banding or lipping.

- Slightly higher cost in some markets; check local pricing.

When to choose which (use-case guidance)

Choose Sainik MR plywood if:

- You want veneered/wooden finish without heavy laminates.

- You need structural plywood for furniture frames, door cores, or shelving that may bear weight.

- You prefer a widely available product with easy local sourcing.

Choose Action TESA HDHMR if:

- You’re building modular kitchens, shutters, bathroom cabinets, or any application continually exposed to humidity.

- Your project requires CNC routing, precise decorative work, or ultra-smooth laminate finishes.

- You need superior screw retention and dimensional stability.

Cost & value considerations

- Initial cost: Sainik MR plywood may be slightly higher, depending on thickness/grade and city, when comparing it with plain HDHMR board. HDHMR can be slightly higher when you go for per-laminated HDHMR board from Action TESA. But per-laminated HDHMR board saves you the extra cost of Laminates (Mica), adhesives (Fevicol) and labour.

- Lifecycle cost: HDHMR often gives lower maintenance in humid areas – fewer replacements due to swelling/delamination.

- Wastage & labour: HDHMR’s uniformity reduces surprises during fabrication; plywood may need more careful handling and finishing.

Installation & good practice

- For either material: seal all edges with PU or edge banding to prevent moisture ingress.

- For kitchens: use HDHMR for carcasses and 19mm plywood board for shutters if you want a mix of cost & finish — but prefer full HDHMR if shutter size is small.

- Always verify batch quality, ask for test certificates, and use recommended adhesives & screws.

Certifications & safety

- Check for BIS/IS standards, formaldehyde emission standards (E0/E1), and manufacturer warranty.

- For Action TESA HDHMR: ask for HMD/HDHMR technical sheet. For Sainik MR: ask for MR certification and veneer grade.

In Action TESA HDHMR vs Sainik MR, HDHMR comes out as the best option for carcasses, and the Century Sainik MR 19mm board is best for shutters.

FAQ

Is HDHMR better than MR plywood for kitchen shutters?

HDHMR offers superior moisture resistance and screw holding for carcasses, but MR plywood board is still best for shutters and where a veneer finish is desired. Must use a 19mm board of MR plywood for shutters.

Can I use them together?

Yes — many contractors use plywood for shutters and HDHMR for carcasses to balance cost and performance.

Which is more durable long-term?

In humid conditions, HDHMR typically lasts longer with less maintenance. For structural load-bearing applications, quality plywood performs very well.

Are these fire resistant?

Neither is inherently fireproof — you can use fire-retardant treated variants if required.